Back to Part 5

Tip shape

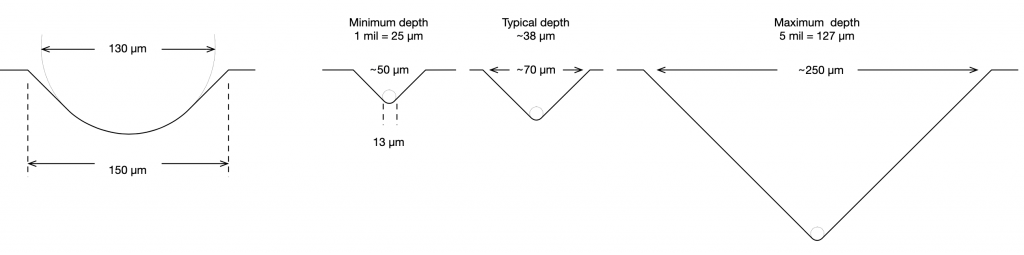

The earliest styli were the needles that were used on 78 RPM gramophone players. These were typically made from steel wire that was tapered to a conical shape, and then the tip was rounded to a radius of about 150 µm, by tumbling them in an abrasive powder.(1) This rounded curve at the tip of the needle had a hemispherical form, and so styli with this shape are known as either conical or spherical.

The first styli made for “microgroove” LP’s had the same basic shape as the steel predecessor, but were tipped with sapphire or diamond. The conical/spherical shape was a good choice due to the relative ease of manufacture, and a typical size of that spherical tip was about 36 µm in diameter. However, as recording techniques and equipment improved, it was realised that there are possible disadvantages to this design.

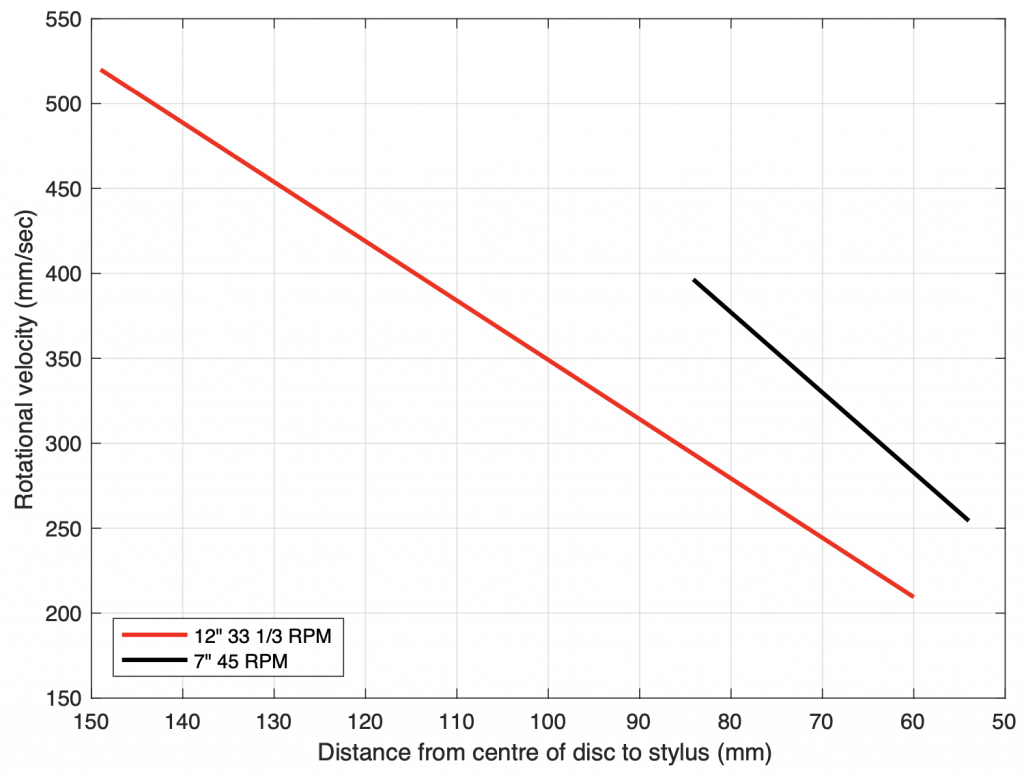

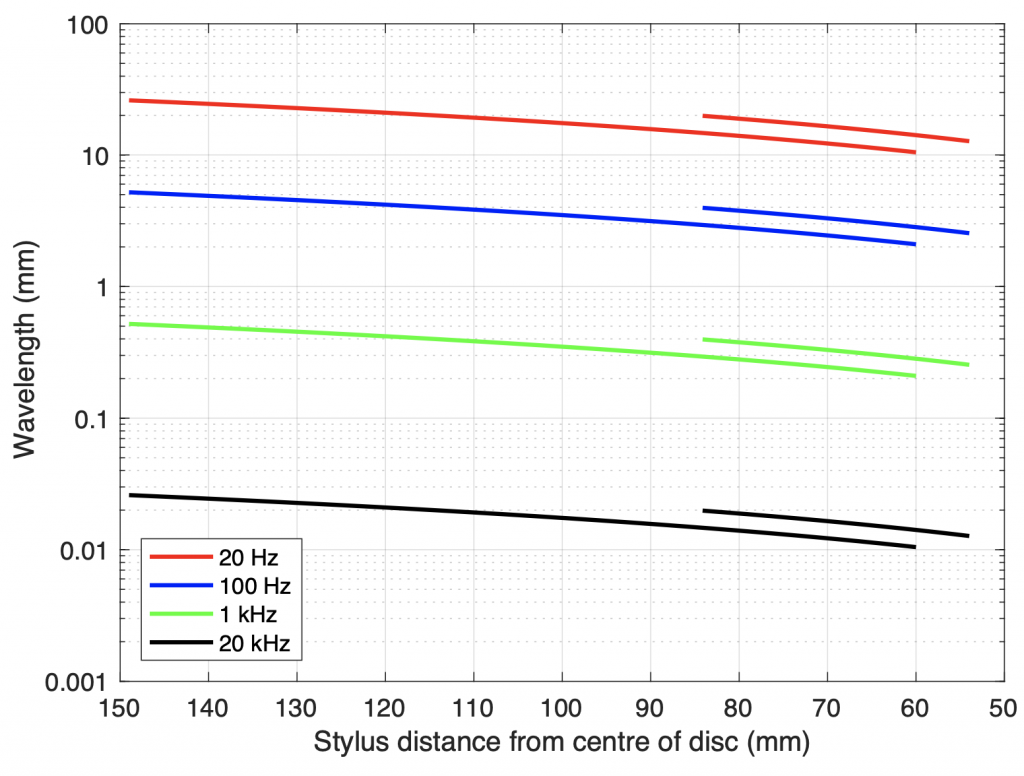

Remember that the side-to-side shape of the groove is a physical representation of the audio signal: the higher the frequency, the smaller the wave on the disc. However, since the disc has a constant speed of rotation, the speed of the stylus relative to the groove is dependent on how far away it is from the centre of the disc. The closer the stylus gets to the centre, the smaller the circumference, so the slower the groove speed.

If we look at a 12″ LP, the smallest allowable diameter for the modulated groove is about 120 mm, which gives us a circumference of about 377 mm (or 120 * π). The disc is rotating 33 1/3 times every minute which means that it is making 0.56 of a rotation per second. This, in turn, means that the stylus has a groove speed of 209 mm per second. If the audio signal is a 20,000 Hz tone at the end of the recording, then there must be 20,000 waves carved into every 209 mm on the disc, which means that each wave in the groove is about 0.011 mm or 11 µm long.

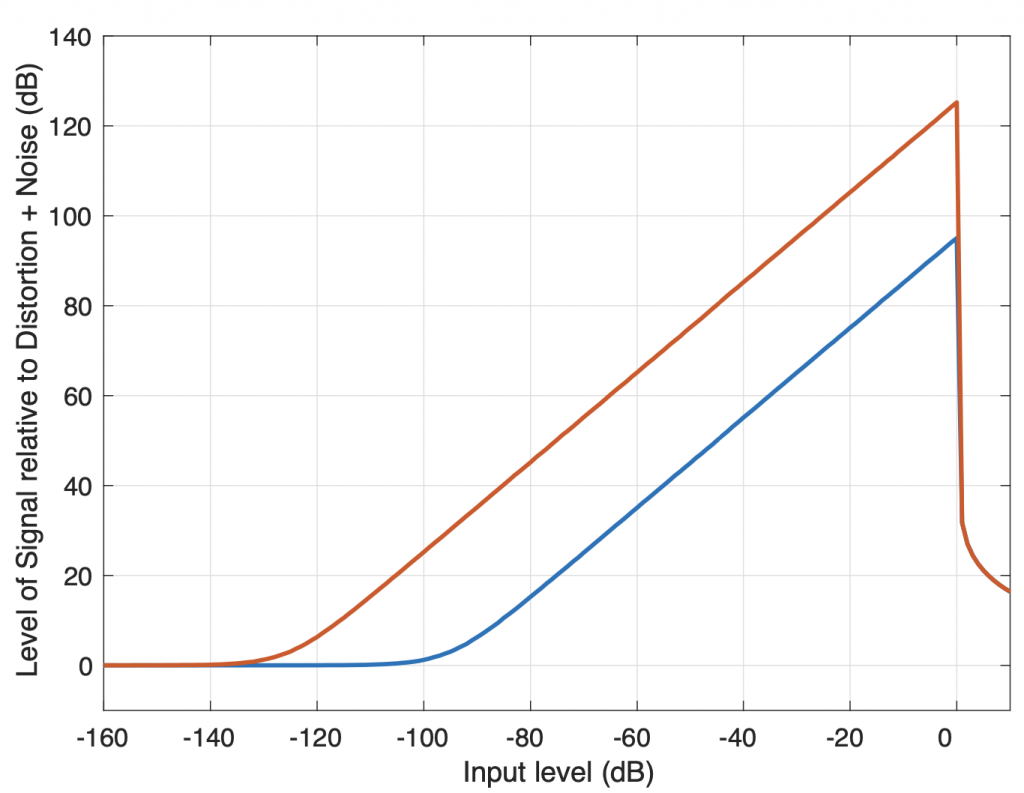

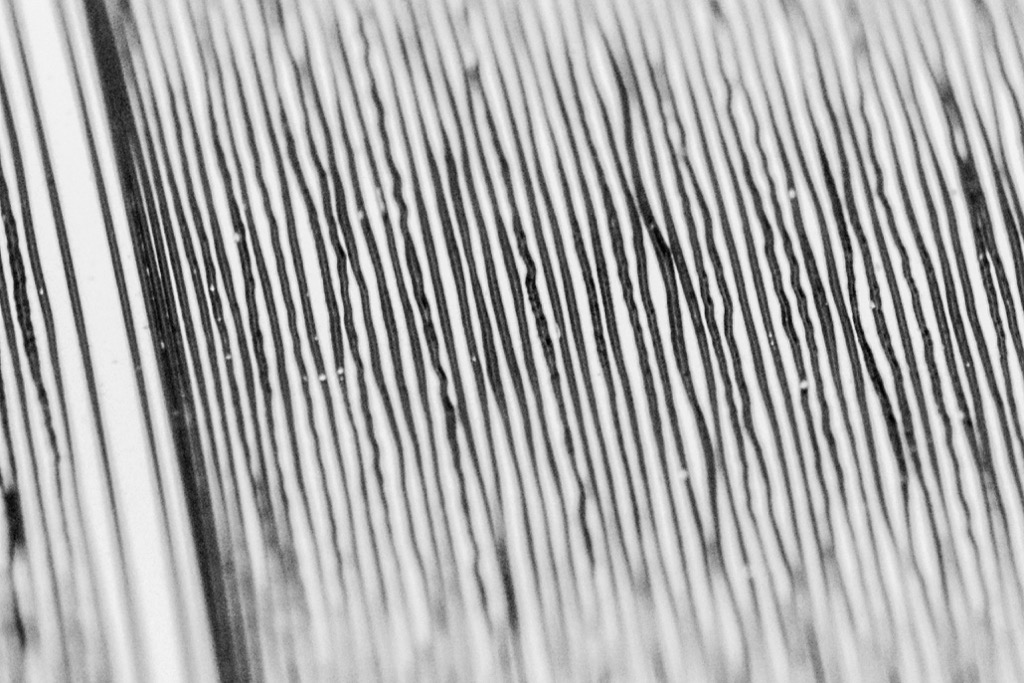

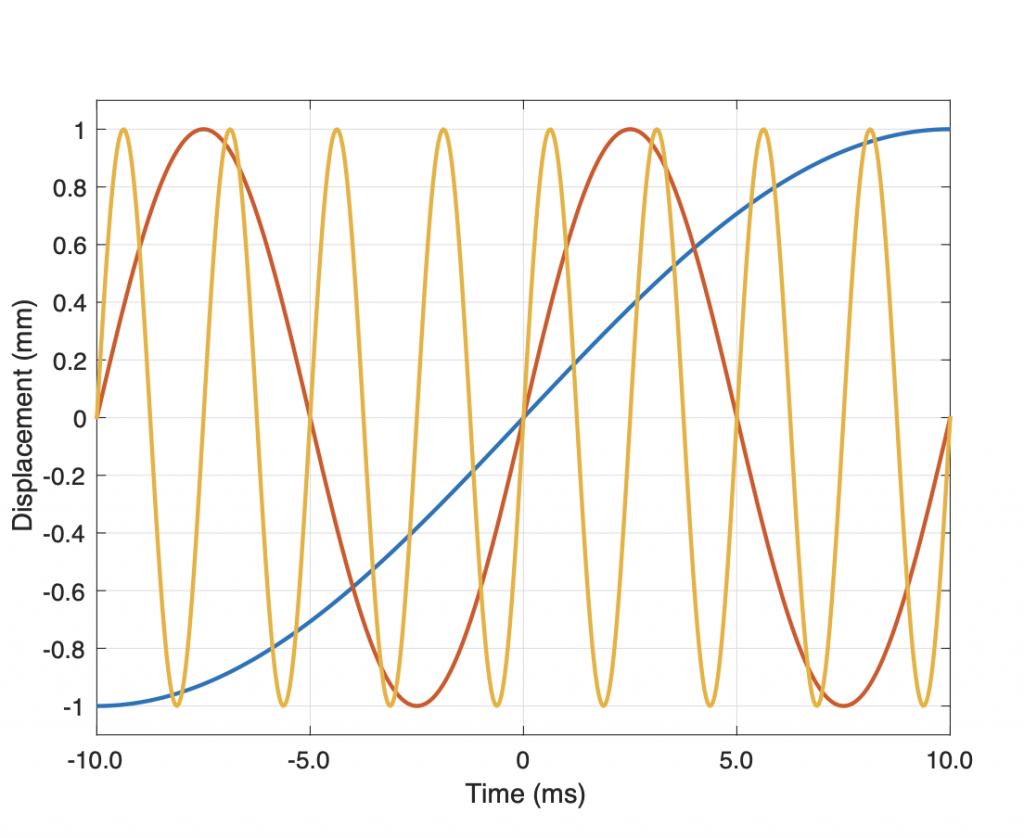

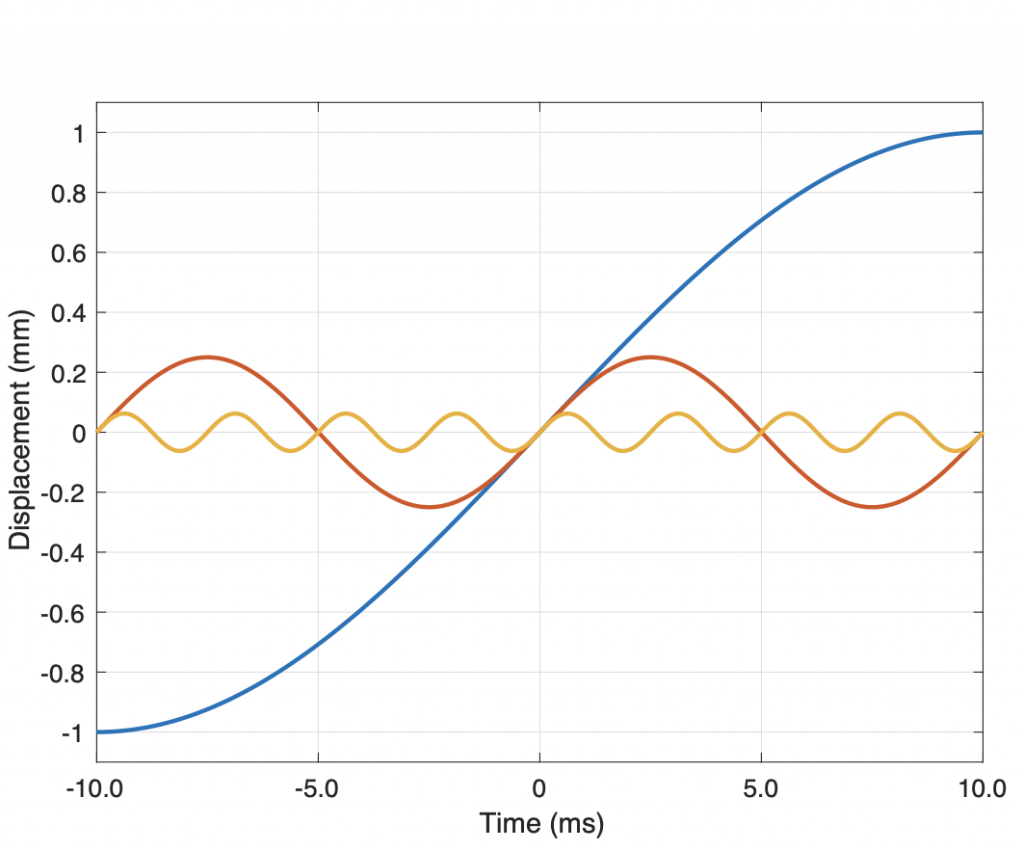

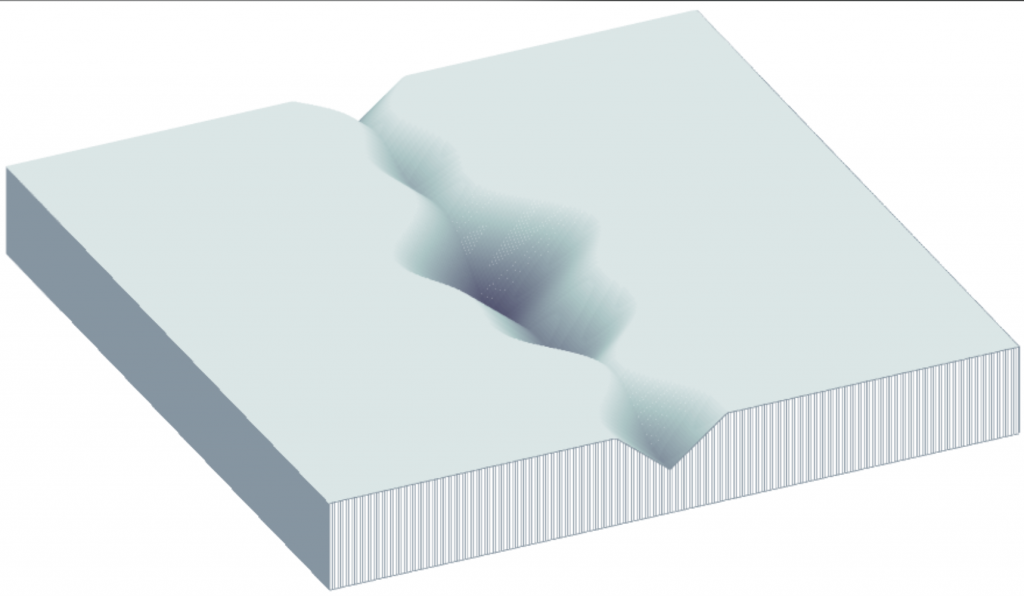

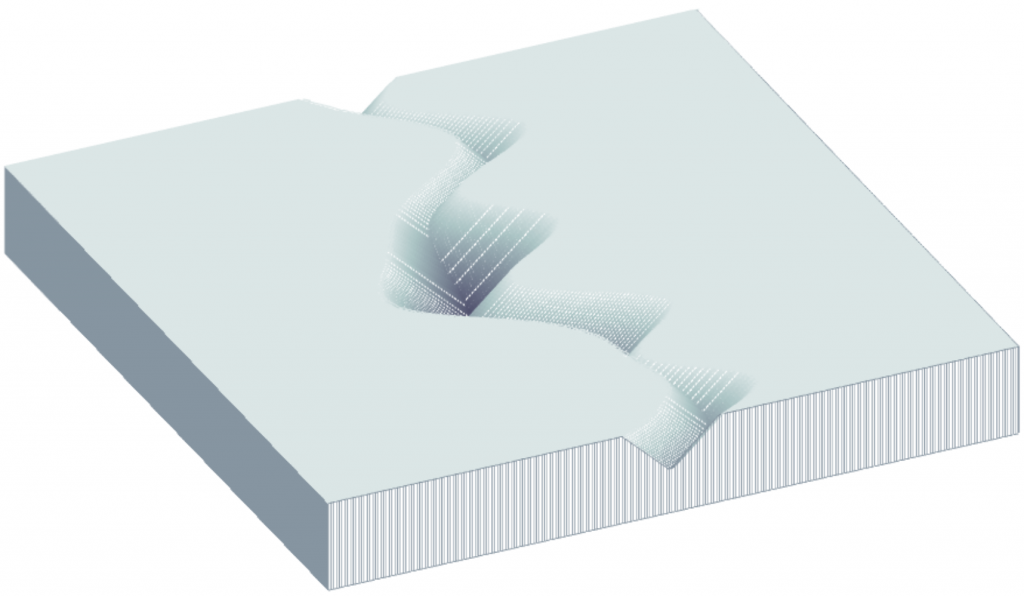

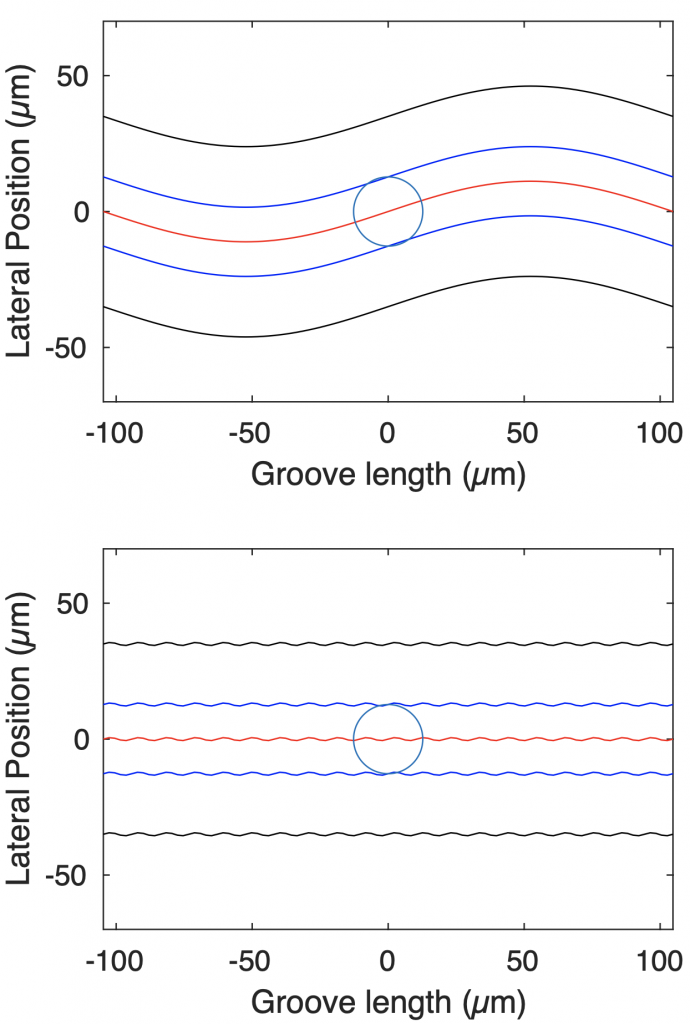

However, now we have a problem. If the “wiggles” in the groove have a total wavelength of 11 µm, but the tip of the stylus has a diameter of about 36 µm, then the stylus will not be able to track the groove because it’s simply too big (just like the tires of your car do not sink into every small crack in the road). Figure 3 shows to-scale representations of a conical stylus with a diameter of 36 µm in a 70 µm-wide groove on the inside radius of a 33 1/3 RPM LP (60 mm from the centre of the disc), viewed from above. The red lines show the bottom of the groove and the black lines show the edge where the groove meets the surface of the disc. The blue lines show the point where the stylus meets the groove walls. The top plot is a 1 kHz sine wave and the bottom plot is a 20 kHz sine wave, both with a lateral modulation velocity of 70 mm/sec. Notice that the stylus is simply too big to accurately track the 20 kHz tone.

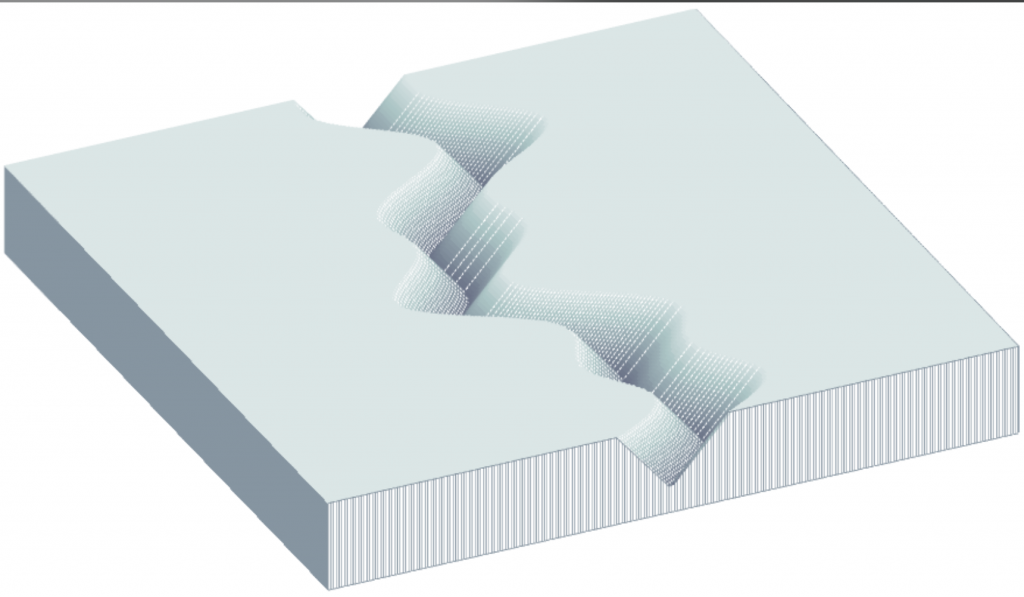

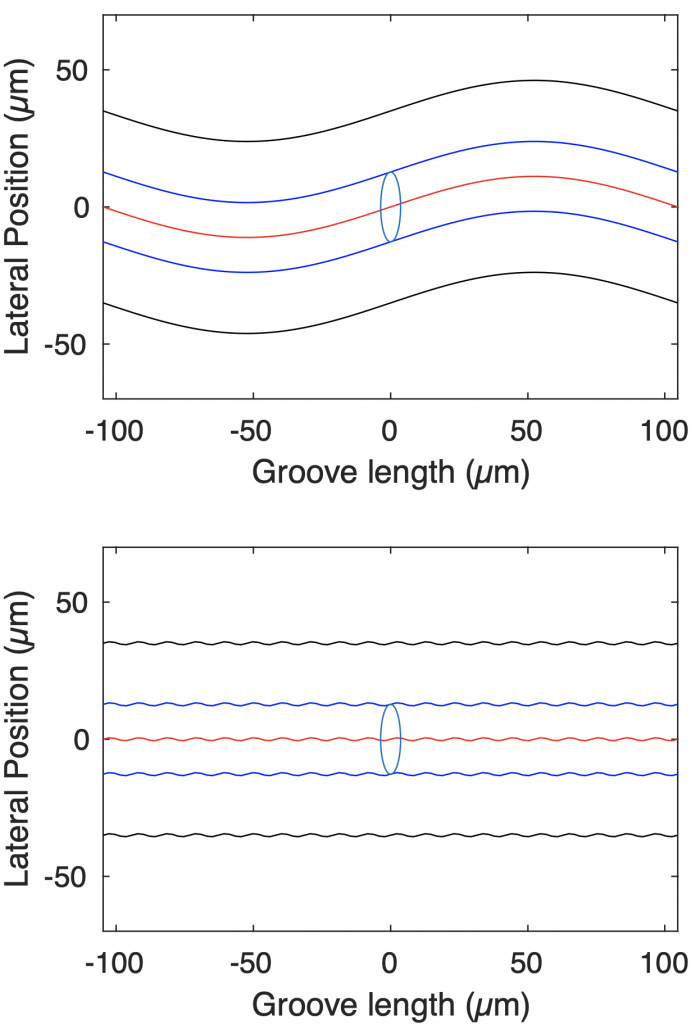

One simple solution was to “sharpen” the stylus; to make the diameter of the spherical tip smaller. However, this can cause two possible side effects. The first is that the tip will sink deeper into the groove, making it more difficult for it to move independently on the two audio channels. The second is that the point of contact between the stylus and the vinyl becomes smaller, which can result in more wear on the groove itself because the “footprint” of the tip is smaller. However, since the problem is in tracking the small wavelength of high-frequency signals, it is only necessary to reduce the diameter of the stylus in one dimension, thus making the stylus tip elliptical instead of conical. In this design, the tip of the stylus is wide, to sit across the groove, but narrow along the groove’s length, making it small enough to accurately track high frequencies. An example showing a 0.2 mil x 0.7 mil (10 x 36 µm) stylus is shown in Figure 4. Notice that this shape can track the 20 kHz tone more easily, while sitting at the same height in the groove as the conical stylus in Figure 3.

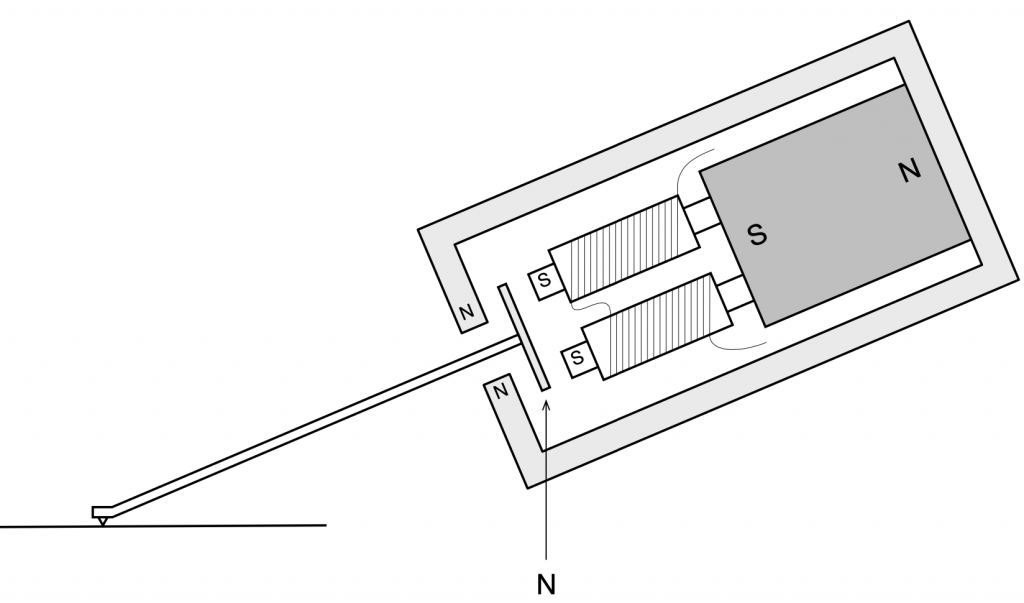

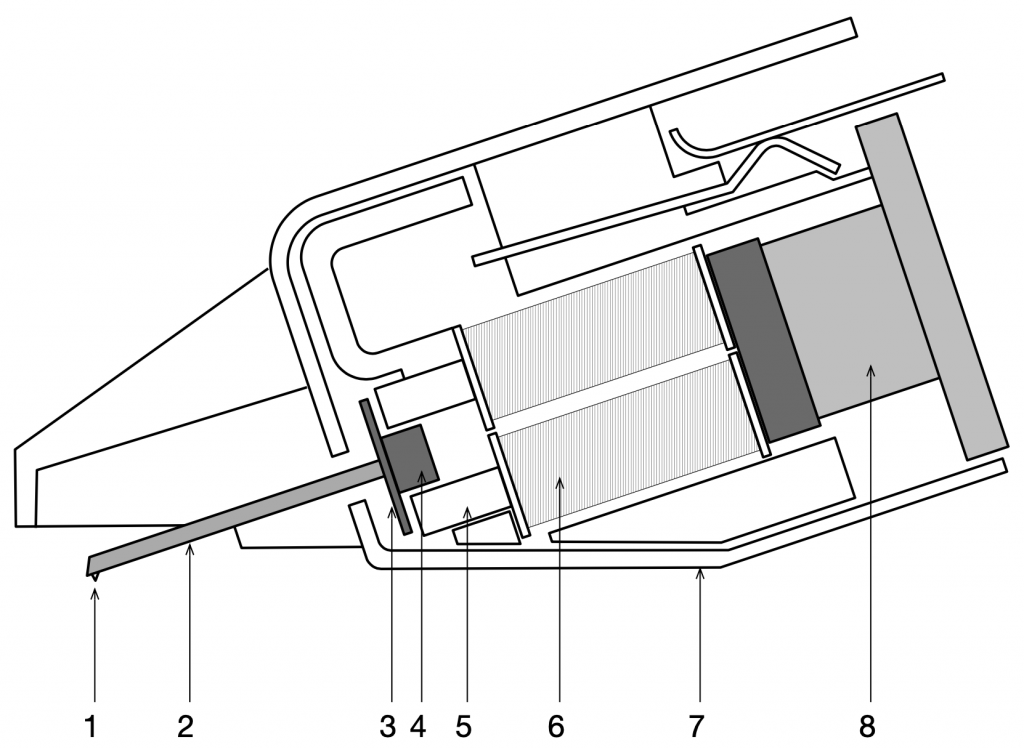

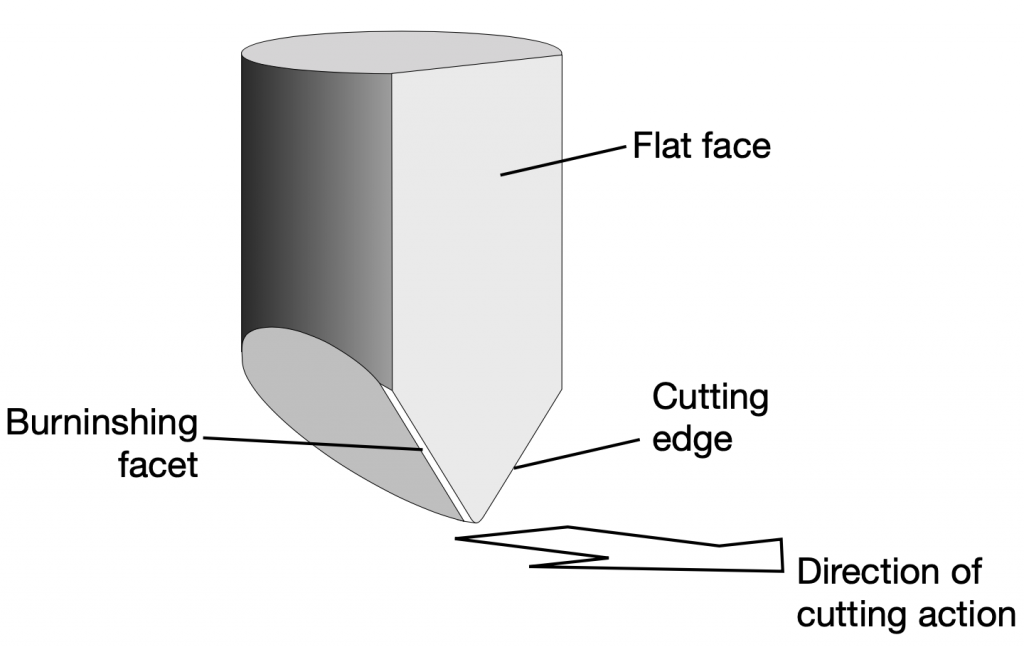

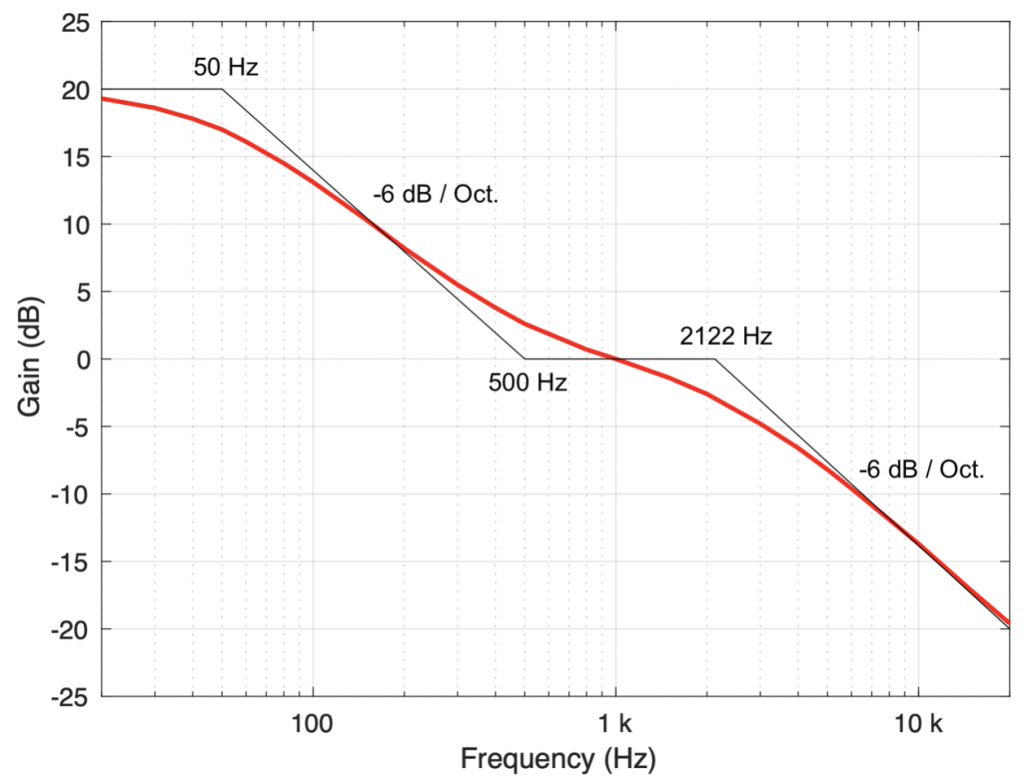

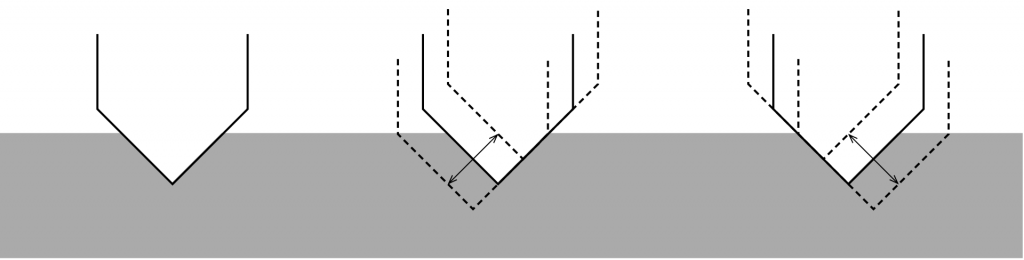

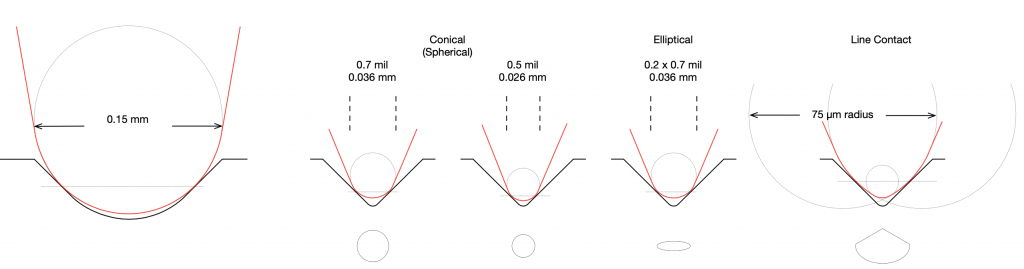

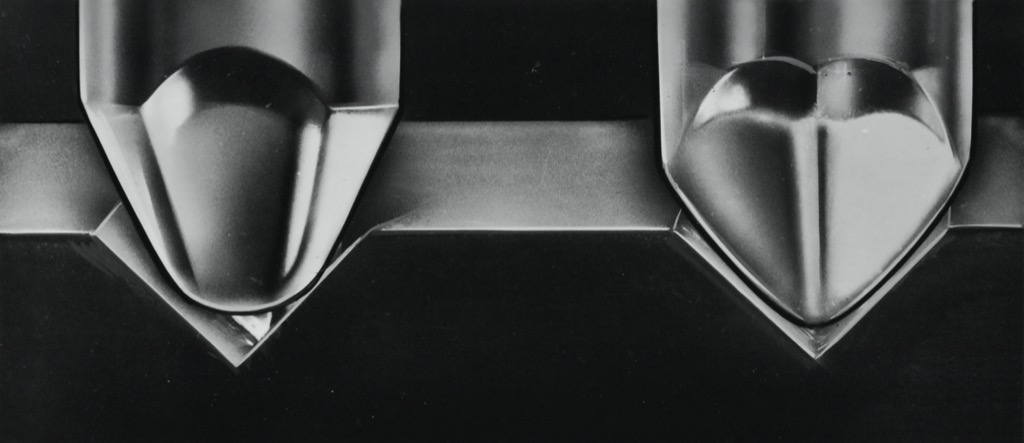

Both the conical and the elliptical stylus designs have a common drawback in that the point of contact between the tip and the groove wall is extremely small. This can be seen in Figure 5, which shows various stylus shapes from the front. Notice the length of the contact between the red and black lines (the stylus and the groove wall). As a result, both the groove of the record and the stylus tip will wear over time, generally resulting in an increasing loss of high frequency output. This was particularly a problem when the CD-4 Quadradisc format was introduced, since it relies on signals as high as 45 kHz being played from the disc.(2) In order to solve this problem, a new stylus shape was invented by Norio Shibata at JVC in 1973. The idea behind this new design is that the sides of the stylus are shaped to follow a much larger-radius circle than is possible to fit into the groove, however, the tip has a small radius like a conical stylus. An example showing this general concept can be seen on the right side of Figure 5.

There have been a number of different designs following Shibata’s general concept, with names such as MicroRidge (which has an interesting, almost blade-like shape “across” the groove), Fritz-Geiger, Van-den-Hul, and Optimized Contour Contact Line. Generally, these designs have come to be known as line contact (or contact line) styli, because the area of contact between the stylus and the groove wall is a vertical line rather than a single point.

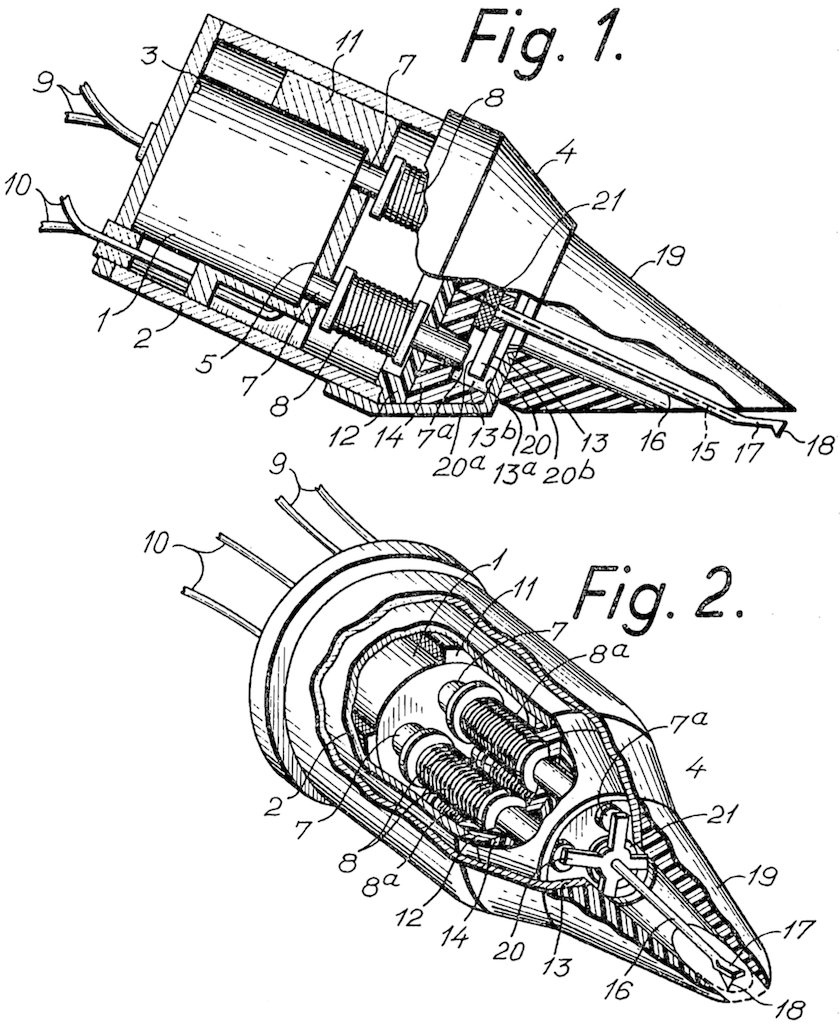

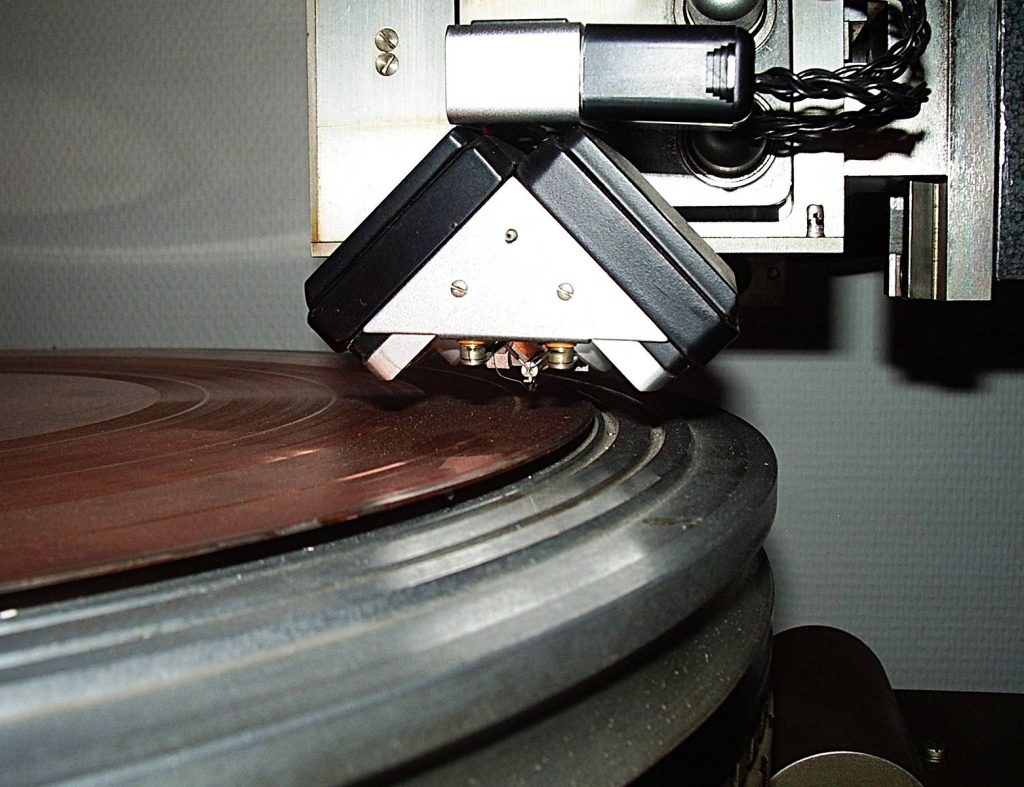

In 1973, Bang and Olufsen started working its own turntable that could play the new CD-4 Quadradisc format. This not only meant developing a new decoder with a 4-channel output, but also a stylus with a bandwidth reliably extending to approximately 45 kHz. This task was given to Villy Hansen, who was project manager for pickup development, despite being still relatively new to the company. Hansen proposed an improvement upon the Shibata grind (which was already commercially available by then) by making 4 facets instead of 2, resulting in a better shape for tracking the very high-frequency modulation. Although developed by Hansen, the new stylus became known as the “Pramanik diamond”, named after Subir K. Pramanik, who had started working as an engineer in Struer in 1971, but who had temporarily returned to India. The end result was a new pickup family that was initially launched with the top model, the MMC 6000.

Bonded vs. Nude

There is one small, but important point regarding a stylus’s construction. Although the tip of the stylus is almost always made of diamond today, in lower-cost units, that diamond tip is mounted or bonded to a titanium or steel pin which is, in turn, connected to the cantilever (the long “arm” that connects back to the cartridge housing). This bonded design is cheaper to manufacture, but it results in a high mass at the stylus tip, which means that it will not move easily at high frequencies.

In order to reduce mass, the steel pin is eliminated, and the entire stylus is made of diamond instead. This makes things more costly, but reduces the mass dramatically, so it is preferred if the goal is higher sound performance. This design is known as a nude stylus.

Footnotes

- See “The High-fidelity Phonograph Transducer” B.B. Bauer, JAES 1977 Vol 25, Number 10/11, Oct/Nov 1977

- The CD4 format used a 30 kHz carrier tone that was frequency-modulated ±15 kHz. This means that the highest frequency that should be tracked by the stylus is 30 kHz + 15 kHz = 45 kHz.

On to Part 7