Day 5’s work can be seen here.

So, it was obvious that the speed regulation wasn’t working properly at the end of Day 5. So, last night was spent digging for information on how centrifugal speed governors work and I came across this excellent explanation.

So, my theory was that the disc was seized on the axle and not moving correctly with the rotational speed. This means that everything came apart again, and the axle had to come out.

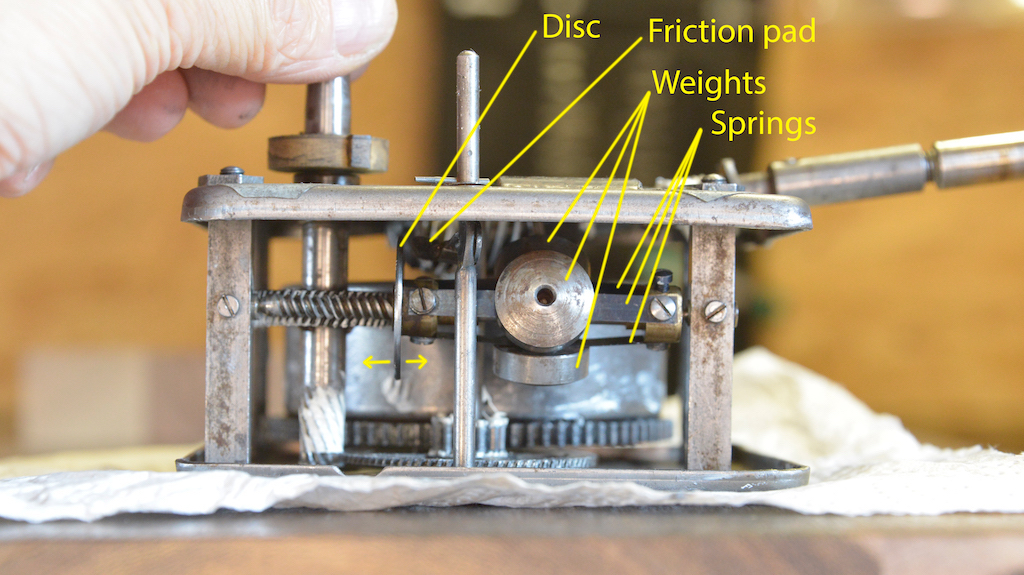

In theory, as the governor spins faster, the three weights get pulled out. This in turn should pull the disc in to rub against the friction pad. When it came out of the motor, the disc was immovable – it was stuck to the axle as I guessed. So, the three springs+weights were removed from the axle and, after a lot of WD-40 and a little repeated gentle “persuasion”, I got to here:

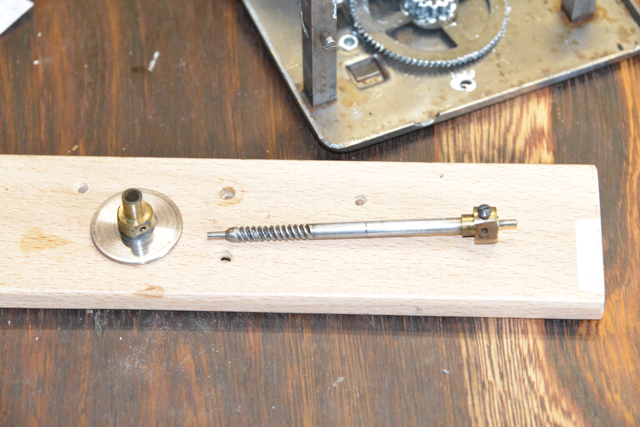

This is after I polished the rust off the axle with sandpaper, starting at 400 and working up to 3200 (lubricated with more WD-40). I was sanding along the length of the axle, since that’s the direction of movement of the disc.

Then it was “just” a matter of putting it all back together again… However, before I put it back in the case, I checked that the governor was working, which you can see below. Notice how the disc moves sideways to meet the friction pad, keeping things at a constant speed.

Then it was just a matter of putting everything back together again… And I have a working Telefunken Lido for those Sunday afternoon garden parties!